Let’s explore the properties and uses of 90-degree elbows. Understanding these aspects will ensure you achieve optimal performance for your application.

Table of contents

- Properties and Uses of 90 Degree Elbow

- 90 Degree Elbow Specification

- SS 90 Degree Elbow Dimensions and Size Chart

- Aluminum 90 Degree Elbow Weight Chart

- 90 Deg Elbow Materials

- Stainless Steel 90 Degree Elbow Pressure Rating

- Copper 90 Degree Elbow Dimensional Tolerance

- 90 Degree Elbow Angularity Tolerances

- 4 inch 90 degree elbow Chemical and Mechanical Properties

- Types of 90° Elbows

- SS 90 Deg Elbows Size Chart

- Advantages of 90 Degree Elbow

Properties and Uses of 90 Degree Elbow

Properties:

- 90-degree bend

- Changing the direction of the flow by a right angle

- Available in various sizes

- Match different pipe diameters and flow rates

- Pressure ratings: depend on the material and design

- End types: threaded, welded, or flanged

- Radius: long radius, short radius

Uses:

To change the direction of a pipeline

Helps in managing the flow of liquids and gases

- Oil and gas refineries

- Chemical plants

- Plumbing

- Power plants

- HVAC systems

90 Deg Elbow are Manufactured as per ASME B16.9 Standard

The ASME B16.9 standard is developed by the American Society of Mechanical Engineers. It applies to industrial butt-weld fittings. This standard defines pressure ratings, sizes, materials, marking, dimensions, surface finish, preparation, fabrication tests, and tolerances.

90 Degree Elbow Specification

| 90 Degree Elbow Size Range |

|

|---|---|

| Standards |

|

| Manufacturing Standards |

|

| Stainless Steel 90 Degree Elbow Thickness |

|

| 4 Inch 90 Degree Elbow Coating |

|

| Aluminum 90 Degree Elbow Type |

|

| Copper 90 Degree Elbow Radius |

|

Refer Sizes and Dimensions of Stainless Steel 90 Degree Elbow

It can be made in several grades of stainless steel, primarily in 304 and 316 SS Grade. It offers good corrosion resistance, high strength, durability, aesthetic appeal, and requires less maintenance.

Check out the below given sizes and dimensions of SS 90 degree elbow.

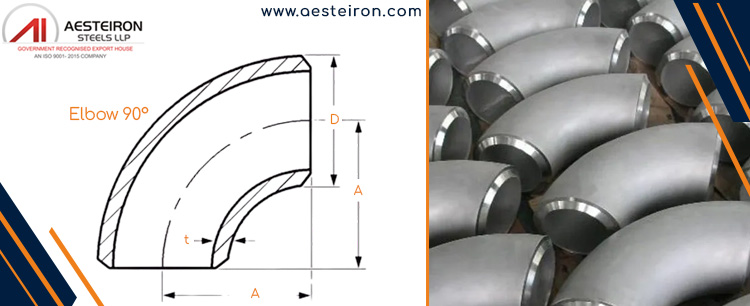

SS 90 Degree Elbow Dimensions and Size Chart

| inch | D | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ND | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 90 | 100 | 125 | |

| mm | 21,34 | 26,67 | 33,40 | 42,16 | 48,26 | 60,32 | 73,02 | 88,90 | 101,60 | 114,30 | 141,30 | |

| Center to center | O | 76,20 | 57,15 | 76,20 | 95,25 | 114,30 | 152,40 | 190,50 | 228,60 | 266,70 | 304,80 | 381,00 |

| Radius | A | 38,10 | 28,57 | 38,10 | 47,60 | 57,15 | 76,20 | 95,25 | 114,30 | 133,35 | 152,40 | 190,50 |

| Back to face | K | 47,62 | 42,86 | 55,56 | 69,85 | 82,55 | 106,40 | 131,80 | 158,75 | 184,15 | 209,55 | 261,90 |

| Center to end | B | 15,87 | 11,11 | 22,22 | 25,40 | 28,57 | 34,92 | 44,45 | 50,80 | 57,15 | 63,50 | 79,38 |

| inch | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 28 | |

| ND | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 700 | |

| mm | 168,27 | 219,07 | 273,05 | 323,85 | 355,60 | 406,40 | 457,20 | 508,00 | 558,80 | 609,60 | 711,20 | |

| Center to center | 457,20 | 609,60 | 762,00 | 914,40 | 1066,80 | 1219,20 | 1371,60 | 1524,00 | 1676,40 | 1828,80 | 2133,60 | |

| Radius | 228,60 | 304,80 | 381,00 | 457,20 | 533,40 | 609,60 | 685,80 | 762,00 | 838,20 | 914,40 | 1066,80 | |

| Back to face | 312,70 | 414,30 | 517,50 | 619,10 | 711,20 | 812,80 | 914,40 | 1016,00 | 1117,60 | 1219,20 | 1422,40 | |

| Center to end | 95,25 | 127,00 | 158,75 | 190,50 | 222,25 | 254,00 | 285,74 | 317,50 | 342,90 | 381,00 | 441,90 |

Check standards and weight chart of copper 90 degree elbow

Copper 90 degree elbow is an adaptable plumbing element which are manufactured to be utilize for several piping and plumbing applications. It presents 90 degree bend along with long radius, which gives smooth and continuous changes in copper pipe installation.

The properties of copper gives exceptional corrosion resistance to the pipe fitting, which helps for smooth water flow with least blockages from rust, hence this makes it safe for water distribution system.

Aluminum 90 Degree Elbow Weight Chart

| NPS (inch) | Â | Â | 01/2 | 03/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LR 90 Deg Elbow | Sch. | 5S | 0.05 | 0.06 | 0.09 | 0.13 | 0.18 | 0.3 | 0.6 | 0.9 | 1.4 | 2.9 |

| Sch. | 10S | 0.06 | 0.07 | 0.15 | 0.2 | 0.3 | 0.5 | 0.85 | 1.3 | 2 | 3.6 | |

| Sch. | 40S | 0.08 | 0.09 | 0.18 | 0.25 | 0.4 | 0.7 | 1.35 | 2 | 4 | 6.5 | |

| Sch. | 80S | 0.1 | 0.11 | 0.2 | 0.35 | 0.5 | 0.9 | 1.8 | 2.9 | 5.9 | 9.7 | |

| SR 90 Deg Elbow | Sch. | 5S | 0.03 | 0.04 | 0.06 | 0.09 | 0.12 | 0.2 | 0.4 | 0.6 | 0.9 | 1.95 |

| Sch. | 10S | 0.04 | 0.05 | 0.1 | 0.13 | 0.2 | 0.33 | 0.6 | 0.9 | 1.35 | 2.4 | |

| Sch. | 40S | 0.05 | 0.06 | 0.12 | 0.17 | 0.27 | 0.47 | 0.9 | 1.35 | 2.65 | 4.35 | |

| Sch. | 80S | 0.07 | 0.07 | 0.13 | 0.12 | 0.33 | 0.6 | 1.2 | 1.9 | 3.9 | 6.5 | |

| NPS (inch) | Â | Â | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| LR 90 Deg Elbow | Sch. | 5S | 4 | 7.4 | 13.6 | 23.4 | 29 | 41.3 | 51.8 | 73 | 122 | |

| Sch. | 10S | 5 | 10 | 16.8 | 27 | 35 | 47 | 59 | 85 | 140 | ||

| Sch. | 40S | 10.5 | 21.5 | 38.5 | 59 | 70 | 95 | 120 | 146 | 210 | ||

| Sch. | 80S | 16 | 33.5 | 52.5 | 79 | 94 | 125 | 158 | 194 | 282 | ||

| SR 90 Deg Elbow | Sch. | 5S | 2.7 | 4.9 | 9.1 | 15.6 | 19.3 | 27.5 | 34.5 | 49 | 82 | |

| Sch. | 10S | 3.35 | 6.7 | 11.2 | 18 | 23.5 | 31.5 | 39.5 | 57 | 94 | ||

| Sch. | 40S | 7 | 14.5 | 25.6 | 39.5 | 47 | 63.5 | 80 | 98 | 140 | ||

| Sch. | 80S | 10.5 | 22.5 | 35 | 53 | 63 | 84 | 105 | 129 | 188 |

90 degree pipe elbow are available in different types of materials such as Stainless steel, Carbon steel and Nickel alloys

It is essential to choose right type of material for 90 degree pipe elbow because wrong material for the application will create problems. Some erosion problems can be originated by using wrong material which are no longer made for the application use.

90 Deg Elbow Materials

| Material | Grades | Characterstics |

|---|---|---|

| Stainless steel 90 deg elbow |

|

|

| Carbon steel 90 degree elbow |

|

|

| Alloy Steel |

|

|

| Duplex / Super Duplex |

|

|

| Nickel Alloy |

|

|

View pressure rating and tolerance chart of ASME B16.9 90 deg elbow

Choosing a correct pressure rating and tolerance will be helpful for the application system to operate well without causing the risk of leakages and damages which provides good safety measure. Find the below given pressure rating and tolerance chart of two different material, which will be helpful for taking precautions against failure.

Stainless Steel 90 Degree Elbow Pressure Rating

| Temperature Ratings | (oF) | -20 to 150 | 500 | 250 | 200 | 300 | 400 | 350 | 450 | 550 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (oC) | -29 to 66 | 260 | 121 | 93 | 149 | 204 | 177 | 232 | 288 | |||

| Pressure Class | 150 | 300 | – | 225 | 265 | 185 | – | 150 | – | – | ||

| 300 | 1/4 – 1 inch. | 2000 | 510 | 1575 | 1785 | 1360 | 935 | 1150 | 725 | 300 | ||

| 1 1/4 – 2 inch. | 1500 | 450 | 1200 | 1350 | 1050 | 750 | 900 | 600 | 300 | |||

| 2 1/2 – 3 inch. | 1000 | 385 | 825 | 910 | 735 | 560 | 650 | 475 | 300 | |||

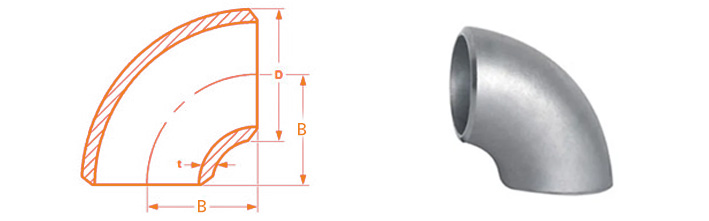

Copper 90 Degree Elbow Dimensional Tolerance

| Nominal Pipe Size | OD | at Bevel (D) | ID at End | Center to End LR (A/B) | Center to End 3D (A/B) | Nominal Pipe Size | OD | at Bevel (D) | ID at End | Center to End LR (A/B) | Center to End 3D (A/B) | Wall Thickness (t) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 to 2.1/2 | 1.6 | -0.8 | 0.8 | 2 | 3 | 10 to 18 | 4 | -3.2 | 3.2 | 2 | 3 | Not less than 87.5% of Nominal Wall Thickness | |

| 3 to 3.1/2 | 1.6 | 1.6 | 2 | 3 | 20 to 24 | 6.4 | -4.8 | 4.8 | 2 | 3 | |||

| 4 | 1.6 | 1.6 | 2 | 3 | 26 to 30 | 6.4 | -4.8 | 6.4 | -4.8 | 3 | 6 | ||

| 5 to 8 | 2.4 | -1.6 | 1.6 | 2 | 3 | 32 to 48 | 6.4 | -4.8 | 6.4 | -4.8 | 5 | 6 | |

90 Degree Elbow Angularity Tolerances

| ND | 1/2 a 4 | 5 a 8 | 10 a 12 | 14 a 16 | 18 a 24 | 26 a 30 | 32 a 42 | 44 a 48 | |

|---|---|---|---|---|---|---|---|---|---|

| Max off plane | P | 2 | 4 | 5 | 7 | 10 | 10 | 13 | 20 |

| Max off angle | Q | 1 | 2 | 3 | 3 | 4 | 5 | 5 | 5 |

4 inch 90 degree elbow Chemical and Mechanical Properties

| Materials | Chemical Properties | Mechanical Properties |

|---|---|---|

| Stainless Steel |

|

|

| Carbon Steel |

|

|

| PVC |

|

|

| CPVC (Chlorinated Polyvinyl Chloride) |

|

|

Types of 90° Elbows

Radiator For Holden,Auto Radiator,Car Radiator Parts For Holden,Holden Radiator

Guangzhou Casselin Trading Co., Ltd. , https://www.casselinautoparts.com