Stockpile measurement refers to the process of determining the size, volume, or weight of a stockpile of materials. This technique is essential for businesses that deal with bulk commodities, as it helps them manage inventory more effectively and reduce waste. These stockpiles are typically found in storage facilities designed for housing large quantities of materials like coal, minerals, fertilizers, and construction aggregates. They are often created by trucks dumping their cargo, bulldozers pushing the material, and workers moving it around. But how do managers know exactly what they have on hand? Historically, workers relied on manual methods or GPS systems that were only accurate within a certain range. These traditional approaches were not only time-consuming but also prone to errors, leading to inefficiencies and potential losses. Today, advancements in technology have revolutionized stockpile measurement. Companies can now use highly accurate tools such as drones, LiDAR, and photogrammetry to get precise measurements quickly and efficiently. This not only improves productivity but also reduces costs across the board. Accurate stockpile measurement is crucial for companies across various industries. Whether you're dealing with coal, ores, fertilizers, or industrial dust, knowing the exact volume of your stockpiles can lead to significant cost savings and operational improvements. Here are some key reasons why stockpile measurement is important: Estimating stockpile sizes manually can lead to overstocking or understocking, both of which can hurt profits. With accurate stockpile measurements, businesses can better manage their inventory, reducing excess stock and associated costs. Additionally, precise data allows companies to plan when to order new supplies or restart mining operations, helping them optimize resource allocation and labor schedules. This leads to lower maintenance costs and more efficient workforce management. Accurate volumetric data also supports better decision-making, ultimately boosting productivity and profitability. Investing in modern stockpile measurement tools can provide a strong return on investment. When collected using advanced technologies, stockpile data can be used for multiple purposes, including financial reporting, tax compliance, and securing loans. The more accurate the data, the easier it is to present it to external stakeholders. Companies can use this data to evaluate their inventory transparently, ensuring they meet regulatory requirements and improve financial planning. Accurate stockpile measurements also help in managing supply chain logistics more effectively. Many industries must comply with strict regulations, especially those involving environmental impact or emissions. For example, the EU Emissions Trading System requires businesses to perform mass balances to calculate CO2 emissions, which is made much easier with accurate stockpile management. Transparency in data collection ensures that regulators can trust the numbers, making audits and compliance checks faster and more efficient. This mutual benefit between businesses and regulatory bodies highlights the importance of accurate stockpile measurement. Stockpile measurement plays a critical role in ensuring worker safety. By providing accurate data, companies can avoid unnecessary risks, such as workers entering unstable or hazardous areas to measure stockpiles manually. Modern tools like drones and LiDAR allow for remote measurements, reducing the need for workers to be exposed to dangerous environments. This not only prevents accidents but also improves overall job satisfaction and efficiency. Additionally, proper stockpile management reduces downtime and maintenance needs, further minimizing the risk of workers being in unsafe positions during repairs. Stockpile measurement is widely used across various industries where bulk materials are stored and managed. Here are some of the key sectors: Aggregates such as sand, gravel, and crushed stone are commonly used in construction. Due to their variable nature, measuring these materials accurately can be challenging. Proper stockpile measurement ensures that different mixes are not mixed together and that inventory is protected from damage. Stockpile aggregates Effective stockpile management helps maintain quality and prevent wastage, making it a vital part of the construction industry. Construction companies rely on stockpile measurements to manage materials like sand, dirt, and asphalt. These measurements help in planning hauling routes and optimizing labor distribution. With accurate data, workers can prepare more efficiently, reducing delays and improving site safety. Mining operations frequently use stockpile measurement to track the volume of materials like iron ore and other minerals. Drones and LiDAR technology have made it possible to measure large stockpiles safely and accurately. Mining sites often have vast stockpiles, and accurate measurement helps in efficient resource management and safety protocols. In recycling and waste management, accurate stockpile measurements are essential for tracking materials and ensuring compliance with environmental regulations. Advanced technologies like drones have significantly improved the accuracy and speed of these measurements. Ports and shipping centers handle large volumes of bulk materials, making stockpile measurement a critical task. Accurate data helps in managing supply chains, reducing fuel consumption, and avoiding costly mistakes. Even small inaccuracies can lead to significant financial losses, making precision a top priority in this sector. There are several methods available for measuring stockpiles, each with its own level of accuracy and application. Here’s an overview of the most common techniques: Traditional manual methods, such as using a walking wheel or estimating by truckload, are still used in some cases. However, these methods are generally less accurate and more time-consuming compared to modern alternatives. While they may be cost-effective, they are not ideal for large-scale or high-precision applications. Smartphones equipped with specialized apps can serve as affordable and effective tools for stockpile measurement. These apps use the phone's camera to capture images, which are then processed to calculate volume. These solutions offer a balance between affordability and accuracy, making them suitable for many small to medium-sized businesses. Photogrammetry involves capturing multiple images of a stockpile and using software to create a 3D model. This method offers high accuracy and is widely used in industries that require detailed measurements. However, it can be expensive and requires skilled operators, making it more suitable for larger organizations. LiDAR technology uses laser pulses to create highly accurate 3D maps of stockpiles. It is particularly useful in low-light conditions and offers greater precision than photogrammetry in some cases. While LiDAR systems are expensive, they are ideal for applications requiring extremely high accuracy, such as in mining and large-scale construction projects. Drones have become one of the most effective tools for stockpile measurement due to their ability to carry various sensors and cameras. Whether it's a photogrammetry sensor, LiDAR scanner, or a simple camera, drones can collect data quickly and efficiently. Different types of drones are suited for different environments. For indoor measurements, compact and durable models like the Elios 3 are ideal, while outdoor operations may require drones with longer battery life and the ability to carry multiple payloads. The Elios 3 has been successfully used in various industries, including mining and construction, to measure stockpiles in challenging environments. Its versatility and accuracy make it a valuable tool for any company looking to improve its stockpile management processes. With the availability of advanced drone technologies like the Elios 3, companies can now achieve faster, more accurate, and safer stockpile measurements. These digital models allow for better reporting, clearer communication, and more reliable tracking of inventory changes. As drone technology continues to evolve, its integration into stockpile management will become even more widespread, offering significant benefits across industries. The future of stockpile measurement looks brighter than ever, thanks to these innovative tools. About Inflatable Beach Ball giant beach ball, mini beach balls, beach soccer ball, inflatable beach ball, cheap beach balls Lixin Outdoor Product Co., Ltd , https://www.pdinflatable.comWhat is Stockpile Measurement?

Sulfur stockpile

Sulfur stockpileWhy Is Stockpile Measurement Important?

It Increases Profitability and Efficiency

It Provides Useful and Reliable Data

It Helps Meet Regulatory Requirements

It Enhances Workplace Safety

What Industries Use Stockpile Measurement?

Aggregates

Construction

Mining

Quarry mine stockpiles

Quarry mine stockpilesRecycling

Shipping and Ports

Stockpile measurement in shipping and ports

Stockpile measurement in shipping and portsStockpile Measurement Methods

Manual Methods

Traditional stockpile measurement with a walking wheel and tape measure

Traditional stockpile measurement with a walking wheel and tape measureSmartphone Applications

Stockpile Lite app

Stockpile Lite appPhotogrammetry

Drone footage on left, photogrammetry 3D model on right

Drone footage on left, photogrammetry 3D model on rightLiDAR

Drones for Stockpile Measurement

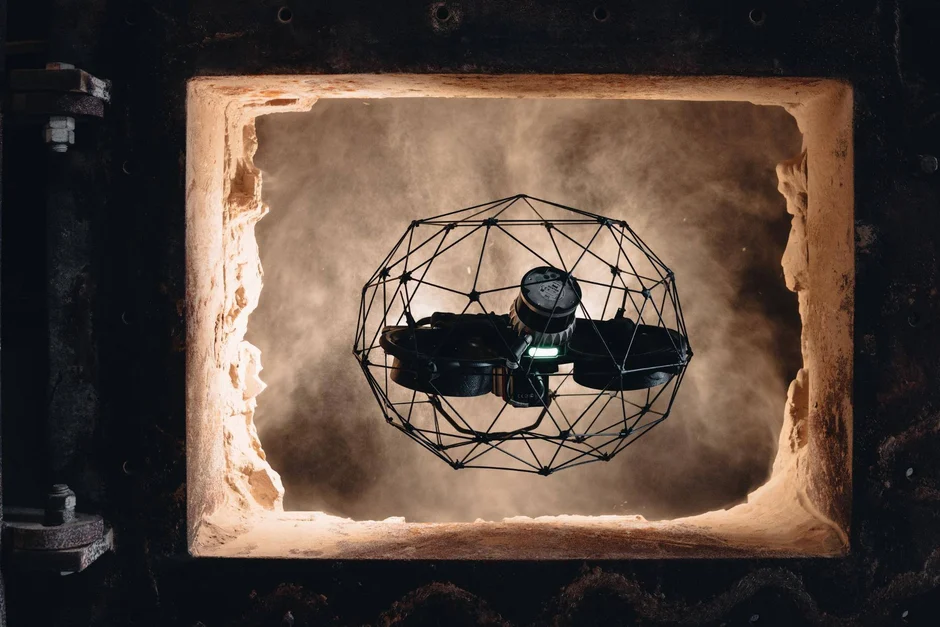

The Elios 3 entering an industrial asset for an inspectionÂ

The Elios 3 entering an industrial asset for an inspection BENEFITS OF DRONES FOR STOCKPILE MEASUREMENT

UPGRADING STOCKPILE MEASUREMENT TECHNIQUES THANKS TO DRONES

Playing beach balls is also an important project for children in seaside games. The inflatable beach ball can make you feel the smooth and sprouts of the volleyball, and it will not make you feel painful.

The beach balls produced by P&D are diverse. The style can be customized, the surface of the ball can be printed or transparent, and the ball can also contain decorations.

The Inflatable Toys played by children pay more attention to safety issues. The sphere is tight and not leaked, and it will not explode in the play.