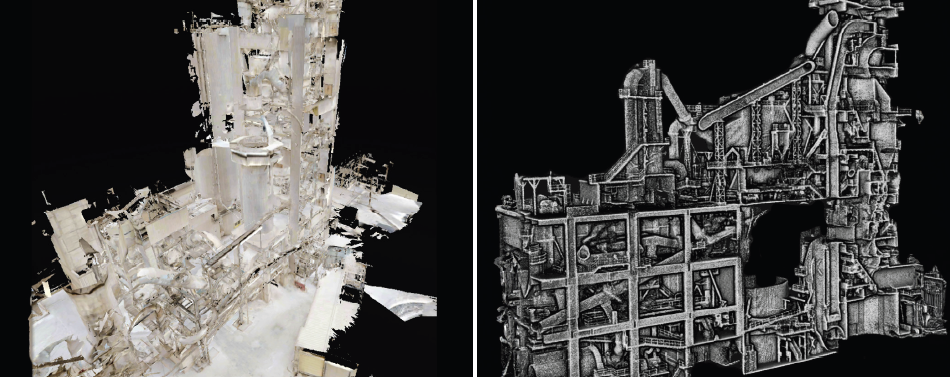

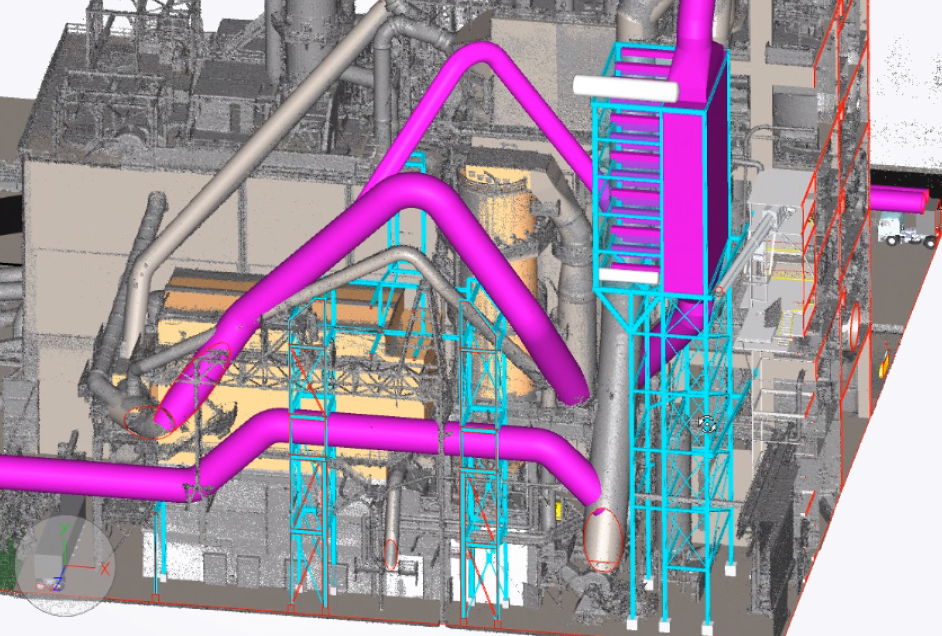

A cement plant in France recently used the Elios 3 drone for a scan-to-BIM project, capturing detailed LiDAR data of the entire site. This innovative approach allowed the team to create a comprehensive digital model of the facility, improving efficiency and accuracy in planning and management. The Elios 3 provided full scans of both the interior and exterior of assets, ensuring no area was left unscanned. This level of detail is difficult to achieve with traditional terrestrial laser scanning. The process can also be repeated easily, allowing for regular updates to the BIM model. Using the Elios 3 reduced the scanning time from at least 10 days to just one day. This dramatic improvement in speed made it possible to complete the project much faster than with conventional methods. The drone’s quick deployment minimized disruption on-site. Instead of having contractors on location for an extended period, the Elios 3 completed its task in a single day, preserving the normal workflow of the plant. The fast data collection and simplified post-processing made the overall process more cost-effective. By using in-house teams, the plant avoided the high costs associated with hiring external contractors. Scan-to-BIM is transforming how infrastructure is managed and designed. Building Information Modeling (BIM) has become a standard in the architecture, engineering, and construction (AEC) industries. It allows for accurate simulations, early problem detection, and better alignment between as-built and as-designed projects. This not only improves communication but also reduces errors, rework, and costs. Holcim, one of the world's leading cement producers, is actively implementing the "Plants of Tomorrow" initiative. This project focuses on integrating Industry 4.0 technologies, including BIM, into the building materials sector. The goal is to modernize plant operations, reduce carbon emissions, and enhance performance across the board. A key part of this initiative involves digitizing assets and production sites. At a plant in France, a project was launched to create a digital twin of the entire facility. This model would help plan future improvements, streamline communication with contractors, and support sustainability efforts by tracking the plant’s environmental impact. The data could also be used to apply for European grants, adding further value to the project. The Elios 3 is already in use at the plant for asset inspections and stockpile monitoring. Pilots are trained to operate the drone safely and trust the quality of its data, which is why it was chosen for the scan-to-BIM project. A laser scan with the Elios 3 captures spaces between pipes and ducts that are hard to access. The challenge of scanning complex industrial environments, where structures and pipes block visibility, made the Elios 3 the ideal choice. Traditional methods would have taken weeks and cost tens of thousands of euros. With the Elios 3, the team completed the work in a single day and processed the data in just two days. A comparison showing the efficiency of the Elios 3 over traditional scanners. By using in-house pilots, the team could quickly adapt to the site conditions and ensure all necessary data was captured without delays or additional costs. This streamlined approach helped avoid the need for multiple trips or re-scans. Creating a BIM model requires a complete and accurate survey of the entire site. In industrial settings, obstacles like pipes and ducts often cause gaps in data. The Elios 3, with its compact and maneuverable design, can navigate tight spaces and capture a full dataset in a single flight. After the scans were completed, the team spent just two days processing the data and refining the model. This included aligning scans from different flights and removing low-quality data such as dust or out-of-range points. The post-processing was done using FARO Connect, the software included with the Elios 3’s Surveying Payload. This ensured the final BIM model was accurate and ready for use in planning and design. The results of this project have had a significant impact on the plant. Using the Elios 3 allowed them to save costs, ensure full coverage, and eliminate the need for multiple scanning sessions. The in-house pilots’ familiarity with the site made the process even smoother and more efficient. This project aimed to create a schematic design, a level 200 BIM model. The Elios 3’s LiDAR data was well-suited for this, providing the right level of detail for the plant’s needs. A schematic design used for engineering layout and spatial planning. With the BIM model in place, the plant can now plan the integration of new systems, such as carbon capture technology, more effectively. The model provides precise measurements and placement for new installations, helping engineers and architects make informed decisions. Additionally, the BIM model serves as a record of the plant’s sustainability efforts, which can be used to apply for funding and demonstrate compliance with environmental standards. This project marks a major step forward in bringing Industry 4.0 technologies to the cement industry. The BIM model has already been shared with subcontractors, proving its value and streamlining project coordination. The benefits of using the Elios 3 are clear: faster data collection, less site disruption, and full data coverage. The cost savings and efficiency gained from this method make it a valuable tool for future projects. Looking ahead, the plant plans to continue using the Elios 3 for remote inspections and asset digitization, ensuring safety and maintaining up-to-date models. As the plant continues to innovate, the Elios 3 remains a key part of its digital transformation journey.

The Silicone For Agriculture mainly including:

Organic Silicone Surfactant,

silicone spreading adjuvant,

spreading agent,

wetting agent,

polyether modified heptamethyltrisiloxane,

super spreader surfactant.

silicone penetration agent,

Defoamer for pesticides,

Advantage: It is a superspreading surfactant based on trisiloxane. 1.Super spreading and penetrating property: Quickly and thoroughly enhance the agro-chemical's penetrability, disperity, absorption, tranportion on the plant. The spreading area and speed of the agro-chemicals on the leaf of plant can be increased greatly.

Organic Silicone Surfactant, silicone spreading adjuvant, organic spreading agent,super wetting agent, Defoamer for pesticides, polyether modified heptamethyltrisiloxane, super spreader surfactant Changzhou Dahua-Luckypower , https://www.czluckypowertech.comDrone Scan to BIM: How the Elios 3 Digitizes a Cement Plant

Key Benefits at a Glance

Comprehensive Data Coverage

Significant Time Savings

Minimal Site Disruption

Cost-Effective Solution

BIM in the Cement Industry

How the Elios 3 Supports Scan-to-BIM

Flying the Elios 3 for BIM Data Collection

Applying the Drone Scan-to-BIM Model

The Future of Drone Scan-to-BIM

2.Improves spray coverage: It can lower the surface tension of spray solutions more effectively than conventional spray adjuvants.

3.High-efficient systemic and conduction property: Increase the agro-chemical's spraying ares, save the dosage of agrochemical by 20-30%, reduce agro-chemical's spraying amount and save cost and protect our environment.

4.Promotes rapid uptake of agrochemicals(rainfastness): Withstand raining-wash, the agro-chemical can be sprayed even in the raining days. 5.Non-toxic, environmental friendly adjuvant.