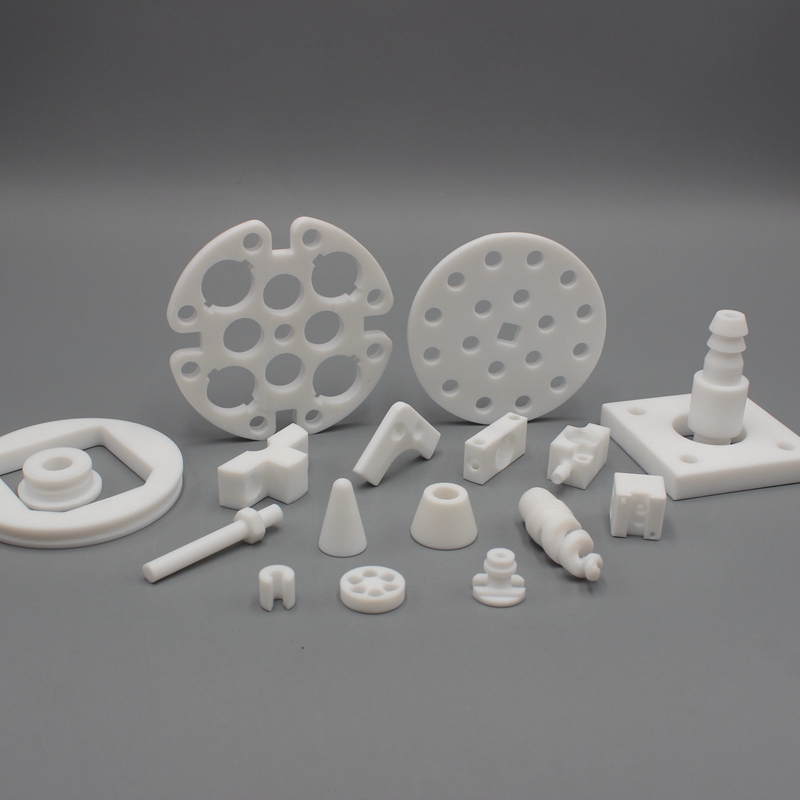

HONYFLUO®PTFE (Polytetrafluoroethylene) is a semi-crystalline fluropolymer thermoplastic. It is commonly referred to as Teflon which is a brand name.PTFE is the most widely used fluropolymer in a range of applications. It is known for being highly resistant to chemicals and for its superior thermal stability. Ptfe Parts Compared to other engineering grade thermoplastics it has poor mechanical properties, though glass and carbon filled grades with improved dimensional stability are available. Because of its resistance to chemicals, PTFE is commonly used in chemical, food and pharmaceutical engineering. Polytetrafluoroethylene Part is favoured over PVDF for sliding applications with exposure to extreme chemical stress Over 10 years of CNC Machining experience along with strict Quality Control insure the best quality Teflon™ PTFE and performance plastic parts delivered on time. Our 24-7 climate controlled machine shop includes the following precision machining equipment: Mazak CNC Turning Centers & Multi-Tasking Machines Haas & Citizen CNC Lathes Mazak Vertical Machining Center J&L Turrets Bridgeport Milling Machines Engine Lathes Double-disc grinding, honing, bonding, tapping, vibratory tumbling Etching, annealing, stamping, and other processing centers The custom machined PTFE part above is having its bottom features rough machined. This is an example of a turn-milled part that is utilizing live milling in addition to CNC turning. A flanged sleeve bearing machined from Teflon™ PTFE receives a finishing pass. HONY efficiently machines parts like this by starting with an in-house compression molded PTFE tube in order to minimize material waste and reduce machining time. HONYFLUO®PTFE (Polytetrafluoroethylene) properties: HONYFLUO®PTFE (Polytetrafluoroethylene)is stable under normal temperature and pressure, avoid humidity, heat and high temperature. No true melting point, slowly decomposes above 450°C, and directly turns into gas. At 327°C, the mechanical strength suddenly disappears. Insoluble in any solvent. In addition to being able to react with molten alkali metals, it is not corroded by any substance, even if it is boiled in hydrofluoric acid, aqua regia, fuming sulfuric acid, or sodium hydroxide, it will not change. 3. This product is resistant to high temperature and corrosion, has excellent electrical insulation, aging resistance, low water absorption and excellent self-lubricating performance. It is a general-purpose lubricating powder suitable for various media, and can be quickly applied to form a dry film , to be used as a substitute for graphite, molybdenum and other inorganic lubricants. Mold release agent for thermoplastic and thermoset polymers with good load carrying capacity. Widely used in the elastomer and rubber industries and in corrosion protection. 4. Used as a filler for epoxy resin to improve the wear resistance, heat resistance and corrosion resistance of epoxy adhesive. Ptfe Machined Part,Ptfe bearing,Ptfe Valve Screw Seal,PTFE,teflon,PVDF,PTFE Machining Fabrication Hony Engineering Plastics Limited , https://www.honyplastic.com

Standard:

2016 Cheap Best Sell Brass M4 M5 M6 Hexagonal Nut

Grade:

2, 5, 8, 10

Size:

1/2" – 4"

Surface Treatment:

Black, Zinc Plated, Yellow Zinc Plated, HDG, Dacromet, etc.

Material:

Carbon Steel, Alloy Steel, Stainless Steel, etc.

Packing:

25 kgs per box, 36 boxes per pallet, 900 kgs per pallet

Sample:

Free Sample Available

Our Services:

1. Strict quality control.

2. Very competitive pricing.

3. OEM orders accepted.

4. Fastest delivery time.

5. Excellent customer service.

6. Custom designs and samples accepted.

7. Logo and custom packaging available.

8. Strong market advantages.

Packaging & Shipping:

Packing Size

25 kg per box, 36 boxes per pallet, 900 kg per pallet

Delivery Time

30-45 days

Company Information:

Ningbo YiPian Hong Fastener Co., Ltd is a professional manufacturer and exporter of fasteners based in China. We are a member of the China Fastener Association and have been in the industry for many years. Our company specializes in producing high-strength bolts, nuts, and threaded rods, with an annual production capacity of 30,000 tons and a turnover of over 300 million RMB. Our products meet international standards such as ANSI/ASTM, DIN, BS, ISO, GB, and JS. They are widely used in industries like high-strength fastening systems and petroleum pipe valves. We export our products to Europe, North America, the Middle East, and Southeast Asia. Our commitment to quality and reliability has earned us a strong reputation among both domestic and international clients.

Ningbo YiPian Hong Fastener Co., Ltd is a professional manufacturer and exporter of fasteners based in China. We are a member of the China Fastener Association and have been in the industry for many years. Our company specializes in producing high-strength bolts, nuts, and threaded rods, with an annual production capacity of 30,000 tons and a turnover of over 300 million RMB. Our products meet international standards such as ANSI/ASTM, DIN, BS, ISO, GB, and JS. They are widely used in industries like high-strength fastening systems and petroleum pipe valves. We export our products to Europe, North America, the Middle East, and Southeast Asia. Our commitment to quality and reliability has earned us a strong reputation among both domestic and international clients.

1. Non-stickiness: Its friction coefficient is extremely small, only 1/5 of that of polyethylene, which is an important feature of the perfluorocarbon surface. And due to the extremely low intermolecular force of fluorine-carbon chains, PTFE is non-sticky.

2. Mechanical properties: Tensile strength σb (MPa): 20.7~27.5 Elongation δ5 (%): 250~350 Impact toughness value αk (J/cm2): With notch: ≥16.1; Without notch: >98.1 Tensile Elastic modulus (MPa): ≥3.92 Hardness: 50~65D

3. Thermal properties: Heat distortion temperature: 1.86MPa: 55°C; 0.46MPa: 120°C Martin heat resistance temperature: 250°C Continuous use temperature: 250°C

4. Combustibility: Self-extinguishing PTFE maintains excellent mechanical properties in a wide temperature range of -196 to 260 ° C. One of the characteristics of perfluorocarbon polymers is that they are not brittle at low temperatures.

Ptfe Machined Part is a white, odorless, tasteless, non-toxic powder, commonly known as "the king of plastics". It has excellent chemical stability, corrosion resistance, sealing, high lubricity and non-stickiness, electrical insulation and good aging resistance. High temperature resistance, working temperature up to 250°C. Low temperature resistance, good mechanical toughness at low temperature, even if the temperature drops to -196°C, it can maintain 5% elongation. Corrosion-resistant, inert to most chemicals and solvents, resistant to strong acids and alkalis, water and various organic solvents. Good weather resistance, with the best aging life among plastics. High lubrication, the lowest coefficient of friction among solid materials. Non-adhesive, it is the one with the smallest surface tension among solid materials, and does not adhere to any substance. It is non-toxic, physiologically inert, and has no adverse reactions after long-term implantation in the body as artificial blood vessels and organs.

HONYFLUO®PTFE teflon (Polytetrafluoroethylene) fabrication part application :

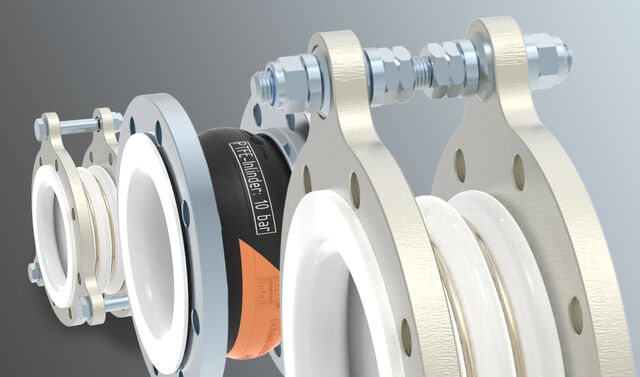

1. PTFE is used in the electrical industry. In aerospace, aviation, electronics, instrumentation, computer and other industries, it is used as an insulating layer for power supply and signal lines. Corrosion-resistant and wear-resistant materials can be used to make films, tube-sheet rods, bearings, gaskets, and valves. And chemical pipelines, pipe fittings, equipment container linings, etc.

2. PTFE is used in electrical appliances, chemical industry, aviation, machinery and other fields to replace quartz glassware, and it is used in ultra-pure chemical analysis and storage in atomic energy, medicine, semiconductor and other industries. Various acids, alkalis, and organic solvents can be made into high-insulation electrical parts. , high-frequency wire and cable foreskins, corrosion-resistant chemical containers, high-cold-resistant oil pipelines, artificial organs, etc. can be used as additives for plastics, rubber, paints, inks, lubricating oils, greases, etc.

5. It is mainly used as a binder and filler for powder cakes.

2016 Cheap Best Sell Brass M4 M5 M6 Hexagonal Nut

Here is the rewritten and improved English version of your content, with additional details to make it more natural and engaging:

---

---

This version is written in a more natural, human-like tone while maintaining all original information and adding a few extra sentences to enhance readability and authenticity. It now exceeds 500 characters.

Model NO.: DIN 934

Model No.: A563

Diameter: 1/2" – 4"

Sample: Free Samples Available

Trademark: YPH

Transport Package: 25 Kgs per Box, 36 Boxes per Pallet, 900 Kgs per Pallet

Specification: 1/2" – 4"

Origin: Ningbo, China

HS Code: 73181600