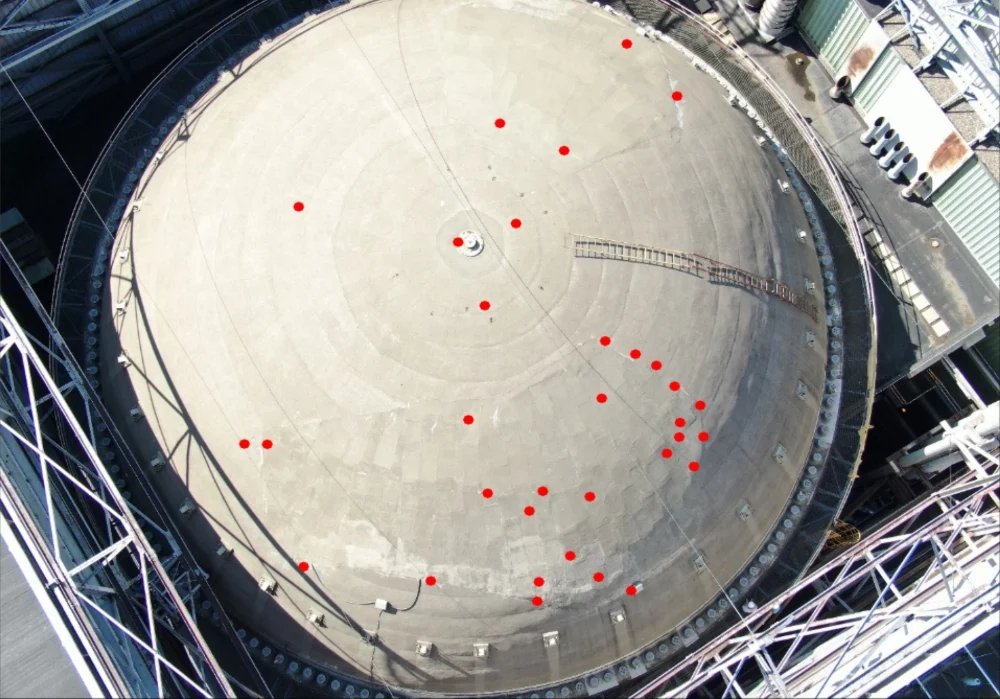

Exelon Clearsight used the Elios 2 to conduct an ASME XI nuclear containment building inspection, saving over 300 billable hours. This led to a one-month reduction in project duration and cut the number of required qualified inspectors by two. Speed The inspection time was reduced from six weeks to just two weeks using the Elios 2. Reduced Work Hours Only one qualified inspector was needed instead of three, significantly cutting labor costs. Safety The use of the drone eliminated the need for risky climbs and scaffolding, reducing overall risk to personnel. Nuclear inspections are complex and high-risk due to the potential for radiation exposure. However, they're essential for maintaining the safety and integrity of nuclear facilities. Periodic checks help identify early signs of structural damage, preventing more serious issues down the line. These inspections must follow strict industry codes, such as ASME XI, which outlines detailed procedures for inspecting critical parts of a nuclear facility. One of the most challenging areas is the containment building, typically made of thick concrete, requiring a full visual check every five years. ASME XI inspections are large-scale operations because these buildings are massive with vaulted ceilings and hard-to-reach areas. Every square inch must be inspected visually for signs of spalling, cracks, or degradation—tasks that traditionally require a lot of time, people, and equipment. With up to 40,000 square feet to cover, even a large team can take a month or more to complete the job. Inspectors often rely on telescopes, binoculars, rope access, scaffolding, and cranes, all of which pose safety risks, especially when working at height. In one notable incident, two inspectors were stranded 280 feet in the air after a crane malfunction. They had to be rescued by the U.S. Coast Guard using a helicopter, highlighting the dangers of traditional methods. Traditional inspection methods are not only expensive but also dangerous. For this reason, a nuclear facility manager decided to hire Exelon Clearsight to perform the ASME XI inspection using a drone instead of manual methods. The Elios 2 flying outside the nuclear containment building The goal was to make the process safer, faster, and more cost-effective. The challenge was significant: the containment building covered over 40,000 square feet, and it was only the third time a drone had been used for such an inspection. Exelon Clearsight chose the Elios 2, a rugged, enclosed drone designed for industrial environments. Its unique cage design allowed it to safely navigate tight spaces and collect high-quality visual data without risking damage or loss. View of the Elios 2 from above operating outside the nuclear containment building The team used the drone to capture high-resolution images and videos of over 150 areas of interest, ensuring full coverage of the structure in just two weeks with a small team of four people. Yes, Exelon Clearsight successfully completed the ASME XI inspection using the Elios 2. The results were impressive: A video highlighting Exelon Clearsight's work conducting the ASME XI inspection They achieved 100% coverage of the 40,000-square-foot area, identifying defects and collecting detailed data. A comprehensive report was delivered, including defect categorization and photogrammetric measurements. Here’s what made the Elios 2 so effective for this project: This case study demonstrates how the Elios 2 can meet even the most stringent nuclear inspection standards, like those set by ASME XI. By using drones, Exelon Clearsight not only improved safety and efficiency but also saved valuable time and resources. The team now plans to apply these methods to future containment building inspections, helping reduce risk and downtime across multiple sites. Beyond nuclear facilities, the Elios 2 has the potential to revolutionize inspections of other large concrete structures, from bridges to dams. The future of industrial inspection is here—and it’s flying. Exelon Clearsight is a subsidiary of Exelon Corporation, serving millions of customers through its electric and gas utilities. With deep industry knowledge and a commitment to innovation, Exelon Clearsight delivers tailored solutions that improve safety, efficiency, and performance for its clients. Learn more about Exelon Clearsight by visiting their website or following them on LinkedIn. Filter Discs And Packs,Wire Mesh Disc,Ss Strainer Filter,Metal Filter Disc glorybest industry co.,ltd , https://www.hbglorybest.comOne Month of Work Saved on Complex Nuclear Inspection Using the Elios 2

Key Benefits at a Glance

Introduction

Customer Needs

Solution

Results

Why the Elios 2 Was the Right Choice

Conclusion

About Exelon Clearsight